Product Description

HN-311 Agricultural Machinery Combine Harvester Cultivator Gear box pto drive shaft

Product Description

Here is our advantages when compare to similar products from China:

| 1. Large output torque |

| 2. Safe, reliable, economical, and durable |

| 3. Stable transmission, quiet operation |

| 4. High modularization design, may equip with various outer power inputs conveniently. The same machine type may equip with various power motors. It is easy to realize the combination and junction between every machine type |

| 5. Form of installation: The position to be installed is not limited |

| 6. High strength, compact the box body of high strength cast iron, gear and gear shaft adopt the gas carbonization, quenching, and fine grinding process, therefore the bearing capacity of unit volume is high |

| 7. Long life: Under the condition of the correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life of the main parts speed reducer(except wearing parts)should not be less than 20000 hours |

| 8. Low noise: Because the main parts of the speed reducer are processed, and tested critically, therefore the noise of the speed reducer is low |

Product Specifications

| ITEM | HN-311 |

| Ratio | 1:3 |

| Teeth | 36/12 |

| Module | 4.35 |

| Power | 50 |

| Rated Input | 540rpm |

| Input/Output Description | 1 3/8 Z6 Optic axis |

| Weight(N.W) | 21Kg |

Packaging & Shipping

Equipment

Certifications

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

Q:WHAT’S THE PAYMENT TERM?

A:When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

Q:HOW TO DELIVER THE GOODS TO US?

A:Usually we will ship the goods to you by sea.

Q:HOW LONG IS YOUR DELIVERY TIME AND SHIPMENT?

A:30-45days.

Q:WHAT’RE YOUR MAIN PRODUCTS?

A:we currently product Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gear pump and motor.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Cultivator Gearbox |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery |

| Material: | 20 Crmnti |

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Agricultural Gearboxes to Farming Machinery Versatility

Agricultural gearboxes play a pivotal role in enhancing the overall versatility of farming machinery. Here’s how they contribute:

- Variable Speeds: Agricultural gearboxes enable machinery to operate at different speeds, allowing farmers to adapt to various tasks. For instance, tractors equipped with adjustable gearboxes can efficiently switch between plowing, seeding, and harvesting.

- Torque Management: Gearboxes control torque delivery to match the requirements of different operations. This ensures optimal power transmission and prevents overloading during tasks like tilling or lifting heavy loads.

- Multi-Functionality: Many farming machines are designed to perform multiple tasks. By incorporating versatile gearboxes, these machines can efficiently switch between functions without requiring major modifications.

- Attachment Compatibility: Farm machinery often requires attachments like mowers, plows, or sprayers. Agricultural gearboxes can be designed to accommodate various attachments, increasing the machinery’s utility and adaptability.

- Adjustable Ratios: Some gearboxes allow operators to change gear ratios on-the-fly. This adaptability is essential for tasks that demand precise control over speed and torque, such as precision planting or spraying.

- Efficient Power Distribution: Gearboxes help distribute power from the engine to different components of the machinery, such as wheels, axles, and implements. This efficient power distribution ensures effective utilization of energy.

- Task-Specific Optimization: Different farming tasks have specific requirements. Agricultural gearboxes can be tailored to optimize machinery performance for tasks ranging from soil preparation to crop maintenance.

- Enhanced Maneuverability: Gearboxes can enable machinery to change directions easily and navigate tight spaces. This is especially valuable in tasks like plowing fields or maneuvering within orchards.

- Adapting to Terrain: Versatile gearboxes allow machines to adapt to different terrains, ensuring consistent performance on various surfaces like hills, slopes, or uneven ground.

- Seasonal Flexibility: Farming involves seasonal tasks that vary in demand and complexity. Gearboxes offer the flexibility to optimize machinery for specific tasks during different seasons, enhancing overall efficiency.

Agricultural gearboxes are a cornerstone of farming machinery versatility, enabling farmers to accomplish a wide range of tasks efficiently and effectively.

Common Signs of Gearbox Wear and Their Solutions

Gearboxes, like any mechanical components, can experience wear over time due to factors such as friction, load, and operating conditions. Recognizing the common signs of gearbox wear is essential for timely maintenance and avoiding potential breakdowns. Here are some signs to watch out for and the solutions to address them:

- Unusual Noises: Grinding, clicking, or whining noises during operation can indicate worn gears or bearings. Inspect the gearbox for damaged teeth or inadequate lubrication. Replace damaged components and ensure proper lubrication.

- Increased Vibration: Excessive vibration suggests misalignment or imbalance within the gearbox. Check for proper alignment and balance the components if necessary. Also, inspect for worn or damaged shafts or bearings.

- Leakage: Oil or lubricant leaks may indicate worn seals or gaskets. Replace seals and gaskets to prevent leakage and ensure adequate lubrication.

- Slipping Gears: Gears slipping out of engagement or difficulty shifting can point to worn or damaged gear teeth. Inspect gears for signs of wear or chipping, and replace as needed.

- Temperature Increase: Abnormal heat generation can result from increased friction due to worn parts. Check lubrication levels and quality, and replace worn bearings or gears causing excess friction.

- Decreased Performance: Reduced power transmission or output efficiency can indicate wear in the gearbox. Inspect gears, bearings, and other components for signs of wear and replace as necessary.

- Excessive Play: Excessive play or backlash in gears can indicate worn gear teeth or bearings. Inspect components for wear, adjust backlash, and replace worn parts.

Addressing gearbox wear requires routine maintenance, including proper lubrication, alignment checks, and regular inspections. Timely replacement of worn or damaged components can extend the gearbox’s lifespan and maintain optimal performance in various applications.

Role of Agricultural Gearboxes in Agricultural Machinery

An agricultural gearbox is a specialized type of gearbox used in various agricultural machinery and equipment. It plays a crucial role in the proper functioning of agricultural equipment by transmitting power and torque from the engine to the different components that perform specific tasks in the field.

Agricultural gearboxes are designed to withstand the demanding conditions of agricultural operations, including exposure to dust, dirt, moisture, and heavy loads. They are commonly used in a wide range of agricultural machinery, including tractors, combines, tillers, sprayers, and more.

The primary functions of agricultural gearboxes include:

- Power Transmission: Agricultural gearboxes transmit power from the engine to various components, such as wheels, blades, and belts, enabling them to perform their respective tasks.

- Speed Control: Gearboxes allow operators to control the speed and output torque of agricultural machinery. Different tasks require different speeds and levels of torque, and gearboxes provide the necessary adjustments.

- Direction Change: Many agricultural operations require changing the direction of rotational motion. Gearboxes enable smooth and efficient direction changes without the need for complex mechanical arrangements.

- Adaptation to Tasks: Agricultural gearboxes are equipped with various gears and shafts that can be configured to match the requirements of specific tasks, such as plowing, planting, harvesting, and more.

These gearboxes come in different configurations, such as straight-cut gears, helical gears, and planetary gears, depending on the specific application and requirements. The choice of gearbox type, gear ratio, and design factors contribute to the overall performance, efficiency, and durability of agricultural machinery.

Regular maintenance and lubrication are essential to ensure the longevity and reliable operation of agricultural gearboxes. Proper care and upkeep help prevent premature wear and damage, ensuring that the machinery performs optimally throughout the farming seasons.

editor by CX 2024-04-29

China Custom RV Series Hollow Shaft Flange 5-100 Ratio Mount Reducer Worm Reduction Gearbox with Best Sales

Product Description

RV Series Hollow Shaft Flange 5-100 Ratio Mount Reducer Worm Reduction Gearbox

Product Description

1. Light in weight and non-rusting

2. Smooth in running, can work a long time in dreadful conditions

3. High efficiency, low noise

4. Good-looking in appearance, durable in service life, and small in volume

Detailed Photos

Product Parameters

| Model | 571 ~ 150 |

| Power | 0.06kw ~ 15kw |

| Input speed | 750rpm ~ 2000rpm |

| Reduction ratio | 1/5 ~ 1/100 |

| Input motor | AC (1 phase or 3 phase) / DC / BLDC / Stepper / Servo |

| Output shaft | Solid shaft / Hollow shaft / Output flange… |

| Dimension standard | Metric size / Inch size |

| Material of housing | die-cast aluminum / Cast iron / Stainless steel |

| Accessories | Flange / CHINAMFG shaft / Torque arm / Cover … |

Our Advantages

Company Profile

FAQ

Q: Can you make the gear unit with customization?

A: Yes, we can customize per your request, like flange, shaft, configuration, material, etc.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard products need s, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, by sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with a different currency, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample 1pc for the normal type and design

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Lubrication Practices for Extending the Lifespan of Agricultural Gearboxes

Proper lubrication is essential for ensuring the longevity and optimal performance of agricultural gearboxes. Here are some essential lubrication practices that can help extend the lifespan of these gearboxes:

- Choose the Right Lubricant: Select a high-quality lubricant specifically designed for gearboxes and agricultural machinery. Consider factors such as viscosity, temperature range, and load-bearing capacity to ensure compatibility with the gearbox’s operating conditions.

- Regular Inspection: Perform regular visual inspections of the gearbox and lubricant to check for signs of contamination, wear, or inadequate lubrication. Address any issues promptly to prevent further damage.

- Cleanliness: Maintain a clean environment around the gearbox to minimize the risk of dirt, debris, and moisture entering the gearbox housing. Contaminants can compromise the lubricant’s effectiveness and accelerate wear.

- Lubricant Level: Monitor and maintain the proper lubricant level in the gearbox. Insufficient lubrication can lead to increased friction and heat, causing premature wear and potential damage to gears and bearings.

- Replace Lubricant: Follow the manufacturer’s recommendations for lubricant change intervals. Over time, lubricants can degrade, lose their properties, and become contaminated. Regularly replacing the lubricant helps ensure optimal performance.

- Use Lubrication Schedule: Create a lubrication schedule based on the gearbox’s usage and operating conditions. Stick to the recommended intervals for applying or changing lubricant to prevent under-lubrication or over-lubrication.

- Appropriate Lubrication Method: Follow the manufacturer’s guidelines for the correct lubrication method, whether it’s through oil bath, grease, or automatic lubrication systems. Proper application ensures even distribution of lubricant across gear surfaces.

- Temperature Considerations: Be aware of temperature variations in your operating environment. Extreme temperatures can affect lubricant viscosity and performance. Choose a lubricant that can handle the temperature range of your equipment.

- Expert Advice: Consult the gearbox manufacturer or a lubrication specialist to determine the best lubrication practices for your specific agricultural gearbox model and application.

By adhering to these lubrication practices, farmers can maximize the lifespan of their agricultural gearboxes, minimize downtime, and ensure efficient and reliable operation of their equipment.

Handling Varying Torque Demands with Agricultural Gearboxes

Agricultural gearboxes are designed to handle the varying torque demands associated with different tasks in farming operations. The torque requirements can vary based on factors such as the type of task, the soil conditions, the terrain, and the machinery’s speed. Agricultural gearboxes are equipped with features that allow them to adapt to these varying torque demands:

- Gear Ratio Selection: Agricultural gearboxes often come with multiple gear ratios, allowing operators to select the appropriate ratio for the task at hand. Lower gear ratios provide higher torque for tasks that require more force, such as plowing or tilling, while higher gear ratios offer higher speeds for tasks like mowing or transporting.

- Torque Multiplier: Some agricultural gearboxes are designed with torque multipliers that enhance the torque output from the engine to the wheels or implement. These multipliers are engaged when higher torque is needed, helping the machinery handle heavy loads or challenging terrain.

- Adjustable Speeds: Many agricultural gearboxes allow operators to adjust the speed of the machinery to match the torque requirements of the task. This flexibility is essential for tasks that involve both high-torque, low-speed operations and high-speed operations with lower torque needs.

- Power Take-Off (PTO) Options: Agricultural gearboxes often feature power take-off mechanisms that enable the transfer of power from the engine to attached implements. These mechanisms can be designed to provide varying torque outputs to suit different implements, such as rotary tillers, balers, or pumps.

The ability of agricultural gearboxes to handle varying torque demands is crucial for ensuring efficient and effective farming operations. By offering adjustable gear ratios, torque multipliers, and adaptable speeds, these gearboxes empower farmers to optimize their machinery’s performance based on the specific requirements of each task.

Maintenance Requirements for Agricultural Gearboxes

Maintaining agricultural gearboxes is crucial to ensure the smooth and efficient operation of farming equipment. Proper maintenance helps extend the lifespan of gearboxes and prevents costly breakdowns. Here are the key maintenance requirements:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, leaks, or misalignment. Regularly inspect gear teeth, seals, and bearings for any issues.

- Lubrication: Proper lubrication is essential to minimize friction and wear in gearboxes. Follow the manufacturer’s guidelines for the type of lubricant to use and the recommended intervals for lubrication.

- Lubricant Checks: Monitor the gearbox’s lubricant levels and quality regularly. Replace or replenish lubricants as needed, and ensure that contaminants are kept out of the lubrication system.

- Tightening Bolts and Fasteners: Check and tighten bolts, nuts, and fasteners to prevent loosening due to vibrations during operation. Loose components can lead to misalignment and premature wear.

- Seal Inspection: Examine seals for leaks and proper sealing. Damaged or worn seals should be replaced promptly to prevent lubricant leakage and the ingress of contaminants.

- Cleaning: Keep gearboxes clean by removing dirt, debris, and residue. Regular cleaning prevents abrasive particles from entering the gearbox and causing damage.

- Alignment: Ensure that gearboxes are properly aligned with connected components, such as shafts and couplings. Misalignment can lead to increased wear and reduced efficiency.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Abnormal temperature increases may indicate issues like overloading or insufficient lubrication.

- Filter Replacement: If the gearbox has a filtration system, regularly replace or clean the filters to prevent contaminants from entering the gearbox.

- Expert Inspection: Periodically have gearboxes inspected by qualified technicians. They can identify potential problems that may not be visible during routine inspections.

Adhering to these maintenance requirements ensures that agricultural gearboxes remain in optimal condition and contribute to the reliability and efficiency of farming equipment. Regular maintenance not only prevents unexpected downtime but also prolongs the service life of the gearboxes, ultimately benefiting the productivity of agricultural operations.

editor by CX 2024-04-26

China Good quality Tractor Parts Pto Drive Transmission Shaft for Agriculture Machinery Ce Certificate with Free Design Custom

Product Description

OEM ODM PTO Shaft for Farm Machine and Agriculture Machine

1. Power or torque related to alternating load you require.

2. Cross journal(Universal joint) size which decides torque of a PTO Shaft:

3 Closed overall length (or cross to cross) of a PTO shaft.

4 Tubes or Pipes

FAQ

1. Q: Are your products forged or cast?

A: All of our products are forged.

2. Q: Do you have a CE certificate?

A: Yes, we are CE qualified.

3. Q: What’s the horse power of the pto shaft are available?

A: We provide a full range of pto shaft, ranging from 16HP-200HP.

4. Q: How many splined specification do you have ?

A: We produce 1 1/8″-Z6, 1 3/8″-Z6, 1 3/4″-Z6, 1 3/8″- Z21, 1 3/4″-Z20, 8X42X48X8 and 8X32X38X6 splines.

5. Q: How about the warranty?

A: We guarantee 1 year warranty. With quality problems, we will send you the new products for free within next shipment.

6. Q: What’s your payment terms?

A: T/T, L/C, D/A, D/P….

7. Q: What is the delivery time?

A: 30 days after receiving your advanced deposit.

8. Q: What’s your MOQ?

A: 50 PCS for each type.

How to Assemble a Pulley System

A pulley is a wheel that rotates on a shaft or shaft to support the movement of a taut cable. Pulleys allow power to be transmitted from the shaft to the cable.

Simple pulley

The simplest theory of operation of a pulley system assumes that the rope and weight are weightless and that the rope and pulley are not stretched. Since the force on the pulley is the same, the force on the pulley shaft must also be zero. Therefore, the force exerted on the pulley shaft is also distributed evenly between the 2 wires passing through the pulley. The force distribution is shown in Figure 1.

The use of simple pulleys is as old as history. Before the Industrial Revolution, people relied on muscle strength to carry heavy loads. Pulleys, levers and ramps make this possible. Today, we can see pulleys in a variety of systems, from exercise equipment to garage doors, and even rock climbers use them to help them reach greater heights. As you can see, these simple machines have been around for centuries and are used in everyday life.

Another simple pulley system is the pulley system. In this system, there is a fixed pulley at the top and a movable pulley at the bottom. The 2 pulleys are connected by a rope. This combination reduces the amount of work required to lift the load. Additionally, the ropes used in this system are usually made of rope and woven through the individual wheels of the pulley drum.

A pulley is an ingenious device that distributes weight evenly and can be used to lift heavy objects. It is easy to build and can be easily modified for a wide range of activities. Even young children can make their own with very few materials. You can also use simple household items such as washing machines, thin textbooks and even chopsticks. It’s very useful and can be a great addition to your child’s science and engineering activities.

The simplest pulley system is movable. The axis of the movable pulley can move freely in space. The load is attached to 1 end of the pulley and the other end to the stationary object. By applying force on the other end of the rope, the load is lifted. The force at the other end of the rope is equal to the force at the free end of the pulley.

Another form of pulley is the compound pulley. Compound pulleys use 2 or more wheels to transmit force. Compound pulleys have 2 or more wheels and can lift heavier objects. Dim is POLE2.

tapered pulley

It is important to clean and align the bolt holes before assembling the tapered pulley. The screws should be lubricated and the threads cleaned before installation. To install the pulley, insert it into the shaft keyway. The keyway should be aligned with the shaft hole to prevent foreign matter from entering the pulley. Then, alternately tighten the bolts until the pulley is tightened to the desired torque.

A tapered pulley is a basic structure. The pulley belt is arranged across 4 steps. Installed between the headstock casting and the main shaft, it is often used in the paper industry. It integrates with printing machinery and supports assembly lines. These pulleys are also available in metric range options, eliminating the need for ke-waying or re-drilling. They are easy to install, and users can even customize them to suit their needs.

CZPT Private Limited is a company that provides unique products for various industries. This large product is used for many different purposes. Also, it is manufactured for industrial use. The company’s website provides detailed specifications for the product. If you need a tapered pulley, contact a company in your area today to purchase a quality product!

Tapered pulleys are vital to paper mill machinery. Its special design and construction enable it to transmit power from the engine source to the drive components. The advantages of this pulley include low maintenance costs and high mechanical strength. Cone wheel diameters range from 10 inches to 74 inches. These pulleys are commonly used in paper mills as they offer low maintenance, high mechanical strength and low wear.

A tapered sleeve connects the pulley to the shaft and forms an interference fit connector. The taper sleeve is fixed on the shaft with a key, and the corresponding inner hole is fixed on the shaft with a key. These features transmit torque and force to the pulley through friction. This allows the tapered pulley to move in a circular motion. The torque transfer characteristics of this pulley are most effective in high speed applications.

The sleeve is the most important part when assembling the tapered pulley. There is an 8-degree taper inside the cone, which is closely connected to the inner surface of the pulley. Taper sleeves and pulleys are interchangeable. However, tapered pulleys can be damaged after prolonged use.

pulley pulley system

A pulley pulley system is a great way to move heavy objects. These systems have been around for centuries, dating back to the ancient Greeks. This simple mechanism enables a person to lift heavy objects. These blocks are usually made of rope, and the number of turns varies for different types of rope. Some blocks have more cords than others, which creates friction and interferes with the easy movement of the lifting system.

When using a pulley pulley, the first thing to decide is which direction to pull. Unfavorable rigging means pulling in the opposite direction. In theory, this method is less efficient, but sometimes requires a certain amount of work space. The benefit is that you will increase the mechanical advantage of the pulley by pulling in the opposite direction. So the interception and tackle system will give you more of a mechanical advantage.

Pulley pulleys are an excellent choice for lifting heavy objects. The system is simple to install and users can easily lift objects without extensive training. Figure 3.40 shows a pulley in action. In this photo, the person on the left is pulling a rope and tying the end of the rope to a weight. When the rope is attached to the load, the rope will be pulled over the pulley and pulley.

The blocks on the blocks are attached to the ends of the rope. This creates unique lifting advantages compared to single-line systems. In Figure 3, the tension of each thread is equal to one-third of the unit weight. When the rope is pulled over the pulley, the force is divided equally between the 2 wires. The other pulley reverses the direction of the force, but that doesn’t add any advantage.

Use pulleys to reduce traction and load. The weight of the load has not changed, but the length of the rope has increased. Using this method, lifting the load by pulling the rope 4 times reduces the force required to lift 1 foot. Likewise, if the pulley system had 4 pulleys instead of three, the length of the rope would be tripled.

The system can transmit loads in any direction. Rope length is determined by multiplying the distance from the fixed block to the load by the mechanical advantage. If the mechanical advantage is 3:1, then passing the rope through the pulley 3 times will produce the required traction distance. Also, the length of the rope will depend on the mechanical advantage, so if the load is 3 times the length of the rope, it will be more than 3 times the required length.

China OEM OEM/ODM Tractor Parts Pto Drive Propeller Shaft for Farm Machine and Agriculture Machine with Free Design Custom

Product Description

OEM Propeller Shaft for Farm Machine and Agriculture Machine

1. Power or torque related to alternating load you require.

2. Cross journal(Universal joint) size which decides torque of a PTO Shaft:

3 Closed overall length (or cross to cross) of a PTO shaft.

4 Tubes or Pipes

FAQ

1. Q: Are your products forged or cast?

A: All of our products are forged.

2. Q: Do you have a CE certificate?

A: Yes, we are CE qualified.

3. Q: What’s the horse power of the pto shaft are available?

A: We provide a full range of pto shaft, ranging from 16HP-200HP.

4. Q: How many splined specification do you have ?

A: We produce 1 1/8″-Z6, 1 3/8″-Z6, 1 3/4″-Z6, 1 3/8″- Z21, 1 3/4″-Z20, 8X42X48X8 and 8X32X38X6 splines.

5. Q: How about the warranty?

A: We guarantee 1 year warranty. With quality problems, we will send you the new products for free within next shipment.

6. Q: What’s your payment terms?

A: T/T, L/C, D/A, D/P….

7. Q: What is the delivery time?

A: 30 days after receiving your advanced deposit.

8. Q: What’s your MOQ?

A: 50 PCS for each type.

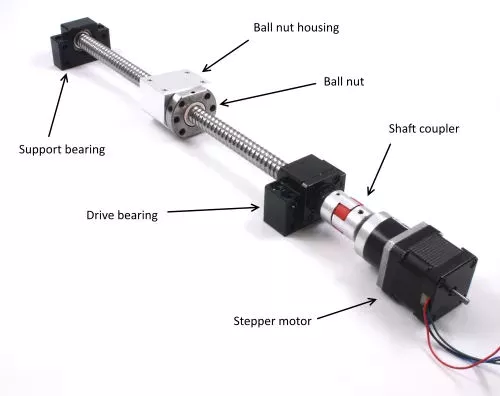

Supporting Ball Screws

In order to use a ball screw in a project, it is important to support it for rotation. Typically, this requires holding brackets and roller bearings. Longer screws may require bending or critical speed restraints. End machining may be necessary to fit the screw into the bearing. Connection to a motor requires coupling and appropriate machining. Tables or support rails may be necessary to restrain the nut.

Cost

In this report, you’ll get an in-depth analysis of the ball screw market. You’ll learn about the competitive landscape, product portfolio, and growth prospects across regions. The report will also include information on the market’s various drivers and restraints, as well as the factors driving or restraining its development. You’ll also get an in-depth look at the value chain and PEST analysis, which are important components of a market study.

One resource that you can use to research the Ball Screw market is CZPT. This website contains a database of authentic Indian manufacturers, suppliers, and importers. You’ll find contact details and email addresses of the companies, including those that produce a wide variety of different types of ball screws. CZPT even allows you to search by product category. That way, you can find a supplier based on the type of ball screw you need at the lowest price.

Another benefit of ball screws is their ability to operate in very delicate applications. In electric vehicles, they are often used to replace a common hydraulic system. They are also used to control gates at hydroelectric stations. You can also find them in motorised inspection tables, step photolithography machines, and microscopic integrated circuits. You can find hundreds of different ball screw designs, and you can even purchase them with nuts, wipers, and CZPT. Ball screws have several bearing balls, which help transfer load between nut and screw. They can be available with adjustable preload and non-preloaded options. And they’re manufactured to industry standards to meet the demands of their users.

If you’re looking for a reliable, high-performing screw, you’ll want to opt for a ball screw. These have high performance-to-cost ratios. You’ll need to choose between a lead screw and a ball screw, but both are reliable and efficient. Besides, the former is less expensive and offers great design flexibility. They’re corrosion-resistant and can even be self-locking for vertical applications.

Applications

A ball screw and nut assembly are essential components of a variety of important actuation and control devices. The 2 components rely on the ability of the screw to rotate easily while converting the rotation into precise lateral movement. Ball screws are a common component in computer-controlled motion-control systems. The precision of ball screw rotation is essential for the accurate adjustment of flight control surfaces. In addition, ball screws are important components of wire bonding and computer-controlled motion-control systems.

Ball screws are highly accurate, requiring minimal lead error. The lead error of a screw is the difference between the theoretical and actual distance traveled by the nut during rotation. The lead error of a ball screw depends on several factors, including the manufacturing accuracy of the ball grooves, the compactness of the assembly, and the set-up precision. This error is not constant from lead to lead, but it may be reduced through preloading, lubrication, and increased mounting accuracy.

The ball is urged to move up and down by rotation of the nut, which is preferably a hexagonal shaft. This allows the ball to be raised easily over the land of the screw. It is important to note that the nut has a groove on the outer surface that is deep enough to accommodate a ball. This groove is deep enough to accommodate a ball, and the groove extends the length of the screw, thereby reducing friction and increasing precision.

The recirculated balls in a multi-start ball screw assembly may cross multiple threads and turn in the circuit. Multi-start ball screw assemblies typically use the internal channel method to recirculate balls. This design allows multiple ball nuts to be used in a single nut and can be easily installed. The ball nut and the nut may also be incorporated into several separate circuits. If several recirculation paths are desired, a ball nut and a multi-start system may be used.

Durability

A key feature of ball screws is their durability. During manufacture, a ball screw’s material must be chosen carefully. A corrosion-resistant steel called Cronidur(r) 30 is an ideal choice. Ball screws made from this material are exceptionally reliable in space due to their alternating steel-ceramic architecture. As the conditions of space are extreme, corrosion-resistant materials are essential to ensure optimum performance. CZPT has decades of experience manufacturing high-quality ball screws. Besides providing a complete range of ball screws, the company also offers technological solutions and dedicated components.

CZPT developed a special design for the High-Durability Precision Ball Screw. This design makes it easier to form a thin film of oil on the material’s surface. This oil helps reduce friction and improve the precision of a ball screw. This material’s special microstructure reduces the wear of ball screws and improves their service life. CZPT also aims to improve the wear-resistance of ball screws.

In addition to the axial load, a ball screw’s life rating should be based on the jacking and vertical loads. In other words, if all load balls are in contact with the raceways, the L-10 life rating of ball screw assemblies would be converted to an L-2 life rating. This change would increase the overall reliability of a ball screw to 98%. Then again, it’s important to note that vertical load is the only 1 that would be completely removed from the chart.

In addition to these important considerations, it is essential to operate ball screws within their recommended operating temperature range. Failure to do so could result in thermal expansion of the ball screw, causing positioning errors. To ensure lubrication of the ball screw, it’s important to keep its operating temperature within the recommended range. However, it is possible to operate it at temperatures that are too high. If this occurs, the screw should be sent to the manufacturer for repair.

Size

Besides their obvious use, ball screws come in 2 sizes, large and small. Although small balls should not show significant wear, they should still be used to enhance the screw’s durability. This can be difficult to determine because screw rebuilders tend to overlook this aspect. So, what is the best size for ball screws? This article will look at both sizes and what they mean for the screw’s durability. Also, we’ll look at some of the things to keep in mind when choosing the right size for your project.

A ball screw’s size depends on its application and performance requirements. Some types have small diameters and fine leads, while others feature large diameters. High precision applications often require miniature ball screws. Some manufacturers even offer compact ball screws with a smaller outer diameter. The latter is commonly found in miniature designs and feature diameters up to 25 mm. However, this doesn’t mean that a smaller diameter means less accuracy. Regardless of the size, you’ll want to make sure to select a screw that will meet your requirements.

The screw’s root diameter is a critical measurement in determining critical speed and column load calculations. A ball screw’s minor diameter is the minimum dimension of the screw shaft at the bottom of the ball grooves. In addition, the idler ball is a necessary component of a ball screw. It prevents friction between the load and idler balls, but does not carry the load itself. Likewise, the non-operating load capacity should be large enough to prevent the balls from brinelling and plastic deformation.

The characteristic speed is the rotational speed at which the ball screw begins to vibrate due to dynamic load. Inch/imperial screws are specified for 1 million revolutions, while metric screw has a specific limit for 1 million inches of linear travel. Various manufacturing processes have their own ways to calculate the useful life of ball screw assemblies. For example, Precision Grinding produces the lowest lead errors. In addition, the life of a ball screw depends on the length of the screw and the mounting support for the end bearings.

Maintenance

It is critical to regularly perform PM on your ball screw assemblies to ensure optimal performance. A dirty ball screw assembly will result in poor performance and faster wear, so removing dirt from the nut and shaft is a good idea. If there are problems with the ball nut, the lubricant inside can become stripped or the nut can become dirty due to chemical exposure. You should also check for oxidation or corrosion on the contact surfaces of the ball screw, and replace it if necessary.

The first sign of a deteriorating ball screw is excessive vibration. This may be caused by a bent screw shaft or misaligned bearing housings. If it makes noise when running, this may be due to excessive build-up or a broken return tube. Other issues may be caused by endplay in support bearings or excessive preload or improper lubrication. If any of these problems are found, it is essential to perform regular maintenance on the ball screw to prolong its life.

Getting regular maintenance on the ball screw assembly is important. If the screw is not properly maintained, it may wear out prematurely. If this happens, you can contact a ball screw repair service. CZPT International, Inc., a leading supplier of industrial parts, can help you get the screw back into optimal working order or find a new one. A ball screw repair company can help you avoid the inconvenience of downtime and maximize your productivity.

It is essential to properly lubricate a ball screw assembly in order to prolong its life. Lubrication can prevent corrosion and increase the life of the screw by 85 percent. It is important to remember that the type of lubricant you use should correspond to the load applied to the assembly. Lubrication should also be done at regular intervals. Once you’ve established the right amount of lubrication, you can then apply it on the screw.

China Custom Cardan Transmission Tractor Spare Parts CZPT Joint Pto Drive Shaft for Agriculture Machinery Jh50 with Great quality

Product Description

Pto Shaft for Agriculture Machinery Jh50

HangZhou CZPT International Trading Co.,Ltd is a modern enterprise specilizing in the development, production, sales and services of PTO shaft. We adhere to the principle of “Precise Driveline, Advocate Green”, using advanced technology and equipments to ensure all the technical standards of precise driveline. So that the transmission efficiency can be maxmized and every drop of resource of customers’ can be saved. Meanwhile, we have a customer-centric service system, providing a full range of pre-sale, sale and after-sale service. Customer satisfaction is our forever pursuit.

We follow the principle of people first, trying our best to set up a pleasant surroundings and platform of performance for each employee, so everyone can be self-consciously active to join in “Precise Driveline, Adocate Green” to embody the self-worth, enterprise value and social value.

Newnuro’s goal is: reducing customer’s purchase budget, support customers to earn more market.

Newnuro always finds solution for customers.Customer satisfaction is our ultimate goal and forever pursuit.

Analytical Approaches to Estimating Contact Pressures in Spline Couplings

A spline coupling is a type of mechanical connection between 2 rotating shafts. It consists of 2 parts – a coupler and a coupling. Both parts have teeth which engage and transfer loads. However, spline couplings are typically over-dimensioned, which makes them susceptible to fatigue and static behavior. Wear phenomena can also cause the coupling to fail. For this reason, proper spline coupling design is essential for achieving optimum performance.

Modeling a spline coupling

Spline couplings are becoming increasingly popular in the aerospace industry, but they operate in a slightly misaligned state, causing both vibrations and damage to the contact surfaces. To solve this problem, this article offers analytical approaches for estimating the contact pressures in a spline coupling. Specifically, this article compares analytical approaches with pure numerical approaches to demonstrate the benefits of an analytical approach.

To model a spline coupling, first you create the knowledge base for the spline coupling. The knowledge base includes a large number of possible specification values, which are related to each other. If you modify 1 specification, it may lead to a warning for violating another. To make the design valid, you must create a spline coupling model that meets the specified specification values.

After you have modeled the geometry, you must enter the contact pressures of the 2 spline couplings. Then, you need to determine the position of the pitch circle of the spline. In Figure 2, the centre of the male coupling is superposed to that of the female spline. Then, you need to make sure that the alignment meshing distance of the 2 splines is the same.

Once you have the data you need to create a spline coupling model, you can begin by entering the specifications for the interface design. Once you have this data, you need to choose whether to optimize the internal spline or the external spline. You’ll also need to specify the tooth friction coefficient, which is used to determine the stresses in the spline coupling model 20. You should also enter the pilot clearance, which is the clearance between the tip 186 of a tooth 32 on 1 spline and the feature on the mating spline.

After you have entered the desired specifications for the external spline, you can enter the parameters for the internal spline. For example, you can enter the outer diameter limit 154 of the major snap 54 and the minor snap 56 of the internal spline. The values of these parameters are displayed in color-coded boxes on the Spline Inputs and Configuration GUI screen 80. Once the parameters are entered, you’ll be presented with a geometric representation of the spline coupling model 20.

Creating a spline coupling model 20

The spline coupling model 20 is created by a product model software program 10. The software validates the spline coupling model against a knowledge base of configuration-dependent specification constraints and relationships. This report is then input to the ANSYS stress analyzer program. It lists the spline coupling model 20’s geometric configurations and specification values for each feature. The spline coupling model 20 is automatically recreated every time the configuration or performance specifications of the spline coupling model 20 are modified.

The spline coupling model 20 can be configured using the product model software program 10. A user specifies the axial length of the spline stack, which may be zero, or a fixed length. The user also enters a radial mating face 148, if any, and selects a pilot clearance specification value of 14.5 degrees or 30 degrees.

A user can then use the mouse 110 to modify the spline coupling model 20. The spline coupling knowledge base contains a large number of possible specification values and the spline coupling design rule. If the user tries to change a spline coupling model, the model will show a warning about a violation of another specification. In some cases, the modification may invalidate the design.

In the spline coupling model 20, the user enters additional performance requirement specifications. The user chooses the locations where maximum torque is transferred for the internal and external splines 38 and 40. The maximum torque transfer location is determined by the attachment configuration of the hardware to the shafts. Once this is selected, the user can click “Next” to save the model. A preview of the spline coupling model 20 is displayed.

The model 20 is a representation of a spline coupling. The spline specifications are entered in the order and arrangement as specified on the spline coupling model 20 GUI screen. Once the spline coupling specifications are entered, the product model software program 10 will incorporate them into the spline coupling model 20. This is the last step in spline coupling model creation.

Analysing a spline coupling model 20

An analysis of a spline coupling model consists of inputting its configuration and performance specifications. These specifications may be generated from another computer program. The product model software program 10 then uses its internal knowledge base of configuration dependent specification relationships and constraints to create a valid three-dimensional parametric model 20. This model contains information describing the number and types of spline teeth 32, snaps 34, and shoulder 36.

When you are analysing a spline coupling, the software program 10 will include default values for various specifications. The spline coupling model 20 comprises an internal spline 38 and an external spline 40. Each of the splines includes its own set of parameters, such as its depth, width, length, and radii. The external spline 40 will also contain its own set of parameters, such as its orientation.

Upon selecting these parameters, the software program will perform various analyses on the spline coupling model 20. The software program 10 calculates the nominal and maximal tooth bearing stresses and fatigue life of a spline coupling. It will also determine the difference in torsional windup between an internal and an external spline. The output file from the analysis will be a report file containing model configuration and specification data. The output file may also be used by other computer programs for further analysis.

Once these parameters are set, the user enters the design criteria for the spline coupling model 20. In this step, the user specifies the locations of maximum torque transfer for both the external and internal spline 38. The maximum torque transfer location depends on the configuration of the hardware attached to the shafts. The user may enter up to 4 different performance requirement specifications for each spline.

The results of the analysis show that there are 2 phases of spline coupling. The first phase shows a large increase in stress and vibration. The second phase shows a decline in both stress and vibration levels. The third stage shows a constant meshing force between 300N and 320N. This behavior continues for a longer period of time, until the final stage engages with the surface.

Misalignment of a spline coupling

A study aimed to investigate the position of the resultant contact force in a spline coupling engaging teeth under a steady torque and rotating misalignment. The study used numerical methods based on Finite Element Method (FEM) models. It produced numerical results for nominal conditions and parallel offset misalignment. The study considered 2 levels of misalignment – 0.02 mm and 0.08 mm – with different loading levels.

The results showed that the misalignment between the splines and rotors causes a change in the meshing force of the spline-rotor coupling system. Its dynamics is governed by the meshing force of splines. The meshing force of a misaligned spline coupling is related to the rotor-spline coupling system parameters, the transmitting torque, and the dynamic vibration displacement.

Despite the lack of precise measurements, the misalignment of splines is a common problem. This problem is compounded by the fact that splines usually feature backlash. This backlash is the result of the misaligned spline. The authors analyzed several splines, varying pitch diameters, and length/diameter ratios.

A spline coupling is a two-dimensional mechanical system, which has positive backlash. The spline coupling is comprised of a hub and shaft, and has tip-to-root clearances that are larger than the backlash. A form-clearance is sufficient to prevent tip-to-root fillet contact. The torque on the splines is transmitted via friction.

When a spline coupling is misaligned, a torque-biased thrust force is generated. In such a situation, the force can exceed the torque, causing the component to lose its alignment. The two-way transmission of torque and thrust is modeled analytically in the present study. The analytical approach provides solutions that can be integrated into the design process. So, the next time you are faced with a misaligned spline coupling problem, make sure to use an analytical approach!

In this study, the spline coupling is analyzed under nominal conditions without a parallel offset misalignment. The stiffness values obtained are the percentage difference between the nominal pitch diameter and load application diameter. Moreover, the maximum percentage difference in the measured pitch diameter is 1.60% under a torque of 5000 N*m. The other parameter, the pitch angle, is taken into consideration in the calculation.

China Custom Tractor Parts Pto Shaft Agriculture Drive Gearbox Rotary Rotavator Tiller Adapter Clutch Cross Cardon CZPT Joint Spline Yoke Driveline Axle Pto Shaft with Good quality

Product Description

Product Description

Company Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was established by Ms. Iris and her 2 partners(Mr. Tian and Mr. Yang) in HangZhou city(ZHangZhoug province, China), all 3 Founders are engineers who have more than averaged 30 years of experience. Then because the requirements of business expansion, in 2014, it moved to the current Xihu (West Lake) Dis. Industrial Zone (HangZhou city, ZHangZhoug province, China).

Through our well-known brand ND, CZPT Machinery delivers agricultural solutions to agriculture machinery manufacturer and distributors worldwide through a full line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, drive shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Products can be customized as request.

We, CZPT machinery established a complete quality management system and sales service network to provide clients with high-quality products and satisfactory service. Our products are sold in 40 provinces and municipalities in China and 36 countries and regions in the world, our main market is the European market.

Our factory

Certifications

Why choose us?

1) Customization: With a strong R&D team, and we can develop products as required. It only takes up to 7 days for us to design a set of drawings. The production time for new products is usually 50 days or less.

2) Quality: We have our own complete inspection and testing equipment, which can ensure the quality of the products.

3) Capacity: Our annual production capacity is over 500,000 sets, also, we also accept small quantity orders, to meet the needs of different customer’s purchase quantities.

4) Service: We focus on offering high-quality products. Our products are in line with international standards and are mainly exported to Europe, Australia, and other countries and regions.

5) Shipment: We are close to HangZhou and ZheJiang ports, to provide the fastest shipping service.

Packaging & Shipping

FAQ

Q: Are you a trading company or manufacturer?

A: We’re factory and providing gearbox ODM & OEM services for the European market for more than 10 years

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time? What is your terms of payment?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization.

For standard products, the payment is: 30% T/T in advance,balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.

Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Types of Splines

There are 4 types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the 2 components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are 3 basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The 2 types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

China Professional OEM/ ODM Tractor Part Pto Drive Cardan Shaft with Free Design Custom

Product Description

OEM ODM Cardan Shaft for Farm Machine and Agriculture Machine

1. Power or torque related to alternating load you require.

2. Cross journal(Universal joint) size which decides torque of a PTO Shaft:

3 Closed overall length (or cross to cross) of a PTO shaft.

4 Tubes or Pipes

FAQ

1. Q: Are your products forged or cast?

A: All of our products are forged.

2. Q: Do you have a CE certificate?

A: Yes, we are CE qualified.

3. Q: What’s the horse power of the pto shaft are available?

A: We provide a full range of pto shaft, ranging from 16HP-200HP.

4. Q: How many splined specification do you have ?

A: We produce 1 1/8″-Z6, 1 3/8″-Z6, 1 3/4″-Z6, 1 3/8″- Z21, 1 3/4″-Z20, 8X42X48X8 and 8X32X38X6 splines.

5. Q: How about the warranty?

A: We guarantee 1 year warranty. With quality problems, we will send you the new products for free within next shipment.

6. Q: What’s your payment terms?

A: T/T, L/C, D/A, D/P….

7. Q: What is the delivery time?

A: 30 days after receiving your advanced deposit.

8. Q: What’s your MOQ?

A: 50 PCS for each type.

Screws and Screw Shafts

A screw is a mechanical device that holds objects together. Screws are usually forged or machined. They are also used in screw jacks and press-fitted vises. Their self-locking properties make them a popular choice in many different industries. Here are some of the benefits of screws and how they work. Also read about their self-locking properties. The following information will help you choose the right screw for your application.

Machined screw shaft

A machined screw shaft can be made of various materials, depending on the application. Screw shafts can be made from stainless steel, brass, bronze, titanium, or iron. Most manufacturers use high-precision CNC machines or lathes to manufacture these products. These products come in many sizes and shapes, and they have varying applications. Different materials are used for different sizes and shapes. Here are some examples of what you can use these screws for:

Screws are widely used in many applications. One of the most common uses is in holding objects together. This type of fastener is used in screw jacks, vises, and screw presses. The thread pitch of a screw can vary. Generally, a smaller pitch results in greater mechanical advantage. Hence, a machined screw shaft should be sized appropriately. This ensures that your product will last for a long time.

A machined screw shaft should be compatible with various threading systems. In general, the ASME system is used for threaded parts. The threaded hole occupies most of the shaft. The thread of the bolt occupy either part of the shaft, or the entire one. There are also alternatives to bolts, including riveting, rolling pins, and pinned shafts. These alternatives are not widely used today, but they are useful for certain niche applications.

If you are using a ball screw, you can choose to anneal the screw shaft. To anneal the screw shaft, use a water-soaked rag as a heat barrier. You can choose from 2 different options, depending on your application. One option is to cover the screw shaft with a dust-proof enclosure. Alternatively, you can install a protective heat barrier over the screw shaft. You can also choose to cover the screw shaft with a dust-proof machine.

If you need a smaller size, you can choose a smaller screw. It may be smaller than a quarter of an inch, but it may still be compatible with another part. The smaller ones, however, will often have a corresponding mating part. These parts are typically denominated by their ANSI numerical size designation, which does not indicate threads-per-inch. There is an industry standard for screw sizes that is a little easier to understand.

Ball screw nut

When choosing a Ball screw nut for a screw shaft, it is important to consider the critical speed of the machine. This value excites the natural frequency of a screw and determines how fast it can be turned. In other words, it varies with the screw diameter and unsupported length. It also depends on the screw shaft’s diameter and end fixity. Depending on the application, the nut can be run at a maximum speed of about 80% of its theoretical critical speed.

The inner return of a ball nut is a cross-over deflector that forces the balls to climb over the crest of the screw. In 1 revolution of the screw, a ball will cross over the nut crest to return to the screw. Similarly, the outer circuit is a circular shape. Both flanges have 1 contact point on the ball shaft, and the nut is connected to the screw shaft by a screw.

The accuracy of ball screws depends on several factors, including the manufacturing precision of the ball grooves, the compactness of the assembly, and the set-up precision of the nut. Depending on the application, the lead accuracy of a ball screw nut may vary significantly. To improve lead accuracy, preloading, and lubrication are important. Ewellix ball screw assembly specialists can help you determine the best option for your application.

A ball screw nut should be preloaded prior to installation in order to achieve the expected service life. The smallest amount of preload required can reduce a ball screw’s calculated life by as much as 90 percent. Using a lubricant of a standard grade is recommended. Some lubricants contain additives. Using grease or oil in place of oil can prolong the life of the screw.

A ball screw nut is a type of threaded nut that is used in a number of different applications. It works similar to a ball bearing in that it contains hardened steel balls that move along a series of inclined races. When choosing a ball screw nut, engineers should consider the following factors: speed, life span, mounting, and lubrication. In addition, there are other considerations, such as the environment in which the screw is used.

Self-locking property of screw shaft

A self-locking screw is 1 that is capable of rotating without the use of a lock washer or bolt. This property is dependent on a number of factors, but 1 of them is the pitch angle of the thread. A screw with a small pitch angle is less likely to self-lock, while a large pitch angle is more likely to spontaneously rotate. The limiting angle of a self-locking thread can be calculated by calculating the torque Mkdw at which the screw is first released.

The pitch angle of the screw’s threads and its coefficient of friction determine the self-locking function of the screw. Other factors that affect its self-locking function include environmental conditions, high or low temperature, and vibration. Self-locking screws are often used in single-line applications and are limited by the size of their pitch. Therefore, the self-locking property of the screw shaft depends on the specific application.

The self-locking feature of a screw is an important factor. If a screw is not in a state of motion, it can be a dangerous or unusable machine. The self-locking property of a screw is critical in many applications, from corkscrews to threaded pipe joints. Screws are also used as power linkages, although their use is rarely necessary for high-power operations. In the archimedes’ screw, for example, the blades of the screw rotate around an axis. A screw conveyor uses a rotating helical chamber to move materials. A micrometer uses a precision-calibrated screw to measure length.

Self-locking screws are commonly used in lead screw technology. Their pitch and coefficient of friction are important factors in determining the self-locking property of screws. This property is advantageous in many applications because it eliminates the need for a costly brake. Its self-locking property means that the screw will be secure without requiring a special kind of force or torque. There are many other factors that contribute to the self-locking property of a screw, but this is the most common factor.

Screws with right-hand threads have threads that angle up to the right. The opposite is true for left-hand screws. While turning a screw counter-clockwise will loosen it, a right-handed person will use a right-handed thumb-up to turn it. Similarly, a left-handed person will use their thumb to turn a screw counter-clockwise. And vice versa.

Materials used to manufacture screw shaft

Many materials are commonly used to manufacture screw shafts. The most common are steel, stainless steel, brass, bronze, and titanium. These materials have advantages and disadvantages that make them good candidates for screw production. Some screw types are also made of copper to fight corrosion and ensure durability over time. Other materials include nylon, Teflon, and aluminum. Brass screws are lightweight and have aesthetic appeal. The choice of material for a screw shaft depends on the use it will be made for.

Shafts are typically produced using 3 steps. Screws are manufactured from large coils, wire, or round bar stock. After these are produced, the blanks are cut to the appropriate length and cold headed. This cold working process pressudes features into the screw head. More complicated screw shapes may require 2 heading processes to achieve the desired shape. The process is very precise and accurate, so it is an ideal choice for screw manufacturing.

The type of material used to manufacture a screw shaft is crucial for the function it will serve. The type of material chosen will depend on where the screw is being used. If the screw is for an indoor project, you can opt for a cheaper, low-tech screw. But if the screw is for an outdoor project, you’ll need to use a specific type of screw. This is because outdoor screws will be exposed to humidity and temperature changes. Some screws may even be coated with a protective coating to protect them from the elements.

Screws can also be self-threading and self-tapping. The self-threading or self-tapping screw creates a complementary helix within the material. Other screws are made with a thread which cuts into the material it fastens. Other types of screws create a helical groove on softer material to provide compression. The most common uses of a screw include holding 2 components together.

There are many types of bolts available. Some are more expensive than others, but they are generally more resistant to corrosion. They can also be made from stainless steel or aluminum. But they require high-strength materials. If you’re wondering what screws are, consider this article. There are tons of options available for screw shaft manufacturing. You’ll be surprised how versatile they can be! The choice is yours, and you can be confident that you’ll find the screw shaft that will best fit your application.

China Custom CZPT Manufacturer wholesale 10% discount front drive shaft with high quality

Model: Other

Year: Other

OE NO.: -2-syz

Automobile Fitment: Other

Dimension: OEM Common Size

Content: Steel

Design Number: SYZ-CJ011

Guarantee: twelve Months

Automobile Make: Automobiles

Item Name: entrance generate shaft

Software: Auto Chassis System

Packing: Neutral Packing

Certification: ISO 9001:2008

OEM: Accpet

Items: Much more than 5000 kinds

Sample: Availabe

Sticker: as call for

Grease nipple: with or with no both okay

Kind: Interior C.V.Joint

Packaging Information: Thread Safety, Separately Bagged, Packed into packing containers for front push shaft cv joint

Port: ZheJiang ,New York,Miami, New Jersey

Honest Company wholesale ten% price cut front generate shaft cv joint

Specifications1.Provide to United states of america,Europe,and Austrilia 2.Matrial:40Cr/ 4130 Warmth Dealt with Chromoly Metal/ 4340 Heat Taken care of Chromoly Metal/ 300M3.Surface: Sand Blast/ Silver Zinc/ Yellow Zinc/ Black Zinc/ Chrome Complete/ ElectrophoresisWe could manufacture all sorts of CV JOINT according to OEM No., Your Samples, or Dawings.

E-mail:product sales(at)racing-suspension.com

Related goods

Manufacturing facility Tour

Top quality Control

Why Choose Us

FAQQ1: How can I get pricing?A1: E mail us OEM No. (Samples or drawings provided be favored), Hot Sell Alternator V-Ribbed Belt Crankshaft Pulley Belt 1340A150 For CZPT Outlander ASX III Lancer ASX SUV 2-2.4L V6 V8 quantity you need to have, if any distinct material or area treatment necessary. We will send you quote within 48 hrs. Q2: How do I get samples?A1: If we have solution in stock, free of charge sample could be presented. If not, we will deliver more than similar item for reference, or make sample for approval with extra value. Q3: What is your payment conditions:A3: Our payment term is 30% in advance, and 70% ahead of shipping and delivery in opposition to copy of B/L. We acknowledge PayPal or Wire Transfer. This fall: What is your shipping terms:A4: We could arrange transport by CZPT to your closest CZPT port, or to your doorway. Air Freight is also obtainable. We could aid just take care of all the import method. CZPT freight will take close to twenty five-forty times, and air freight takes 3-7 times. Q5: Do you examination your items before shipping and delivery, what if there is any good quality dilemma? A5: We 100% take a look at our goods before delivery. If any top quality problem does come about, we will substitute all the defective kinds at our shipping value, FLYER CE certificated 4 wheel drive 60hp 70hp 80hp diesel engine 46cylinder 4X4 agricultural farming tractor provide or refund to you. Q6: What about guide time?A6: For very first get, usually lead time about 45-60 times. For repeat purchase, generally close to thirty-45 times.Q7: Do you make personalized parts? A7: Completely absolutely Sure! Outperforming the factory first is what we do. We could make components according to your sample or drawing, and we could offer recommendations on how to layout the items to make it more robust!

Speak to Us

More than 5 years knowledge,we can give specialist remedies for consumers.

Deliver your inquiry details in the underneath,click “Deliver” Now! OURI Truck Belt Tensioner Pulley for CZPT motor 89422 49537 3103249 3934814 GT36095 !!

What is a driveshaft and how a lot does it cost to exchange one particular?